Turbines

MicroturbinesMicroturbines represent a new kind of gas turbines. Their commercial application started in 1998. Microturbine capacity ranges from 25 to 500 kW as a distributed energy source. They can also be used as the CHP technology exploiting waste heat which increases energy efficiency to more than 80%. Microturbines have a wide application in industry and for commercial purposes. Their “fridge size” doesn’t require huge space. They can be fired, besides fossil fuels, by biogas or landfill gas which combines utilization of renewable energy sources and cogeneration technology.

In comparison with other small capacity technologies, microturbines have numerous advantages such as reliable power supply capability, use on remote locations and during peak load, easier maintenance, longer lifetime, relatively lower noise emission, higher efficiency, lower greenhouse gases emission and a fast start.

Basic microturbine disadvantages, in the current development phase, are a relatively modest experience of its use and higher expenses in comparison with gas engines, which could be decreased by their wider commercial utilization.

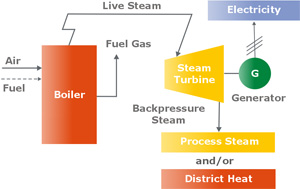

Steam turbinesAs CHP technology, steam turbines have been widely used in the USA and Europe. A special design which increases steam efficiency has been developed. These turbines can be fired by fossil fuels such as coal, oil and natural gas or by renewable energy sources such as wood and city waste. Because of their wide use, different requirements and features, there is a range of steam turbines of different design and capacity exceeding 50 kW.

In conventional steam power plants high-pressure steam expands within the steam turbine and goes into the capacitor as a low-pressure steam. If steam turbines are used as CHP technology, steam can be utilized directly for industrial processes or household heating via heat exchangers.

Gas turbinesGas turbines are economically cost-effective CHP technology for industry and commercial consumer sector alike, ranging in its capacity from 1 to 20 MW.

“Rejected” gas turbine heat can be further used for obtaining steam needed for additional steam turbine. This system is called CCCT – combined cycle combustion turbine in which two separate processes or cycles use the same fuel via primary turbine.

They have especially been popularized in the USA, where are used for district heating. Their highly quality heat can be used in most mid-pressure steam systems. They are widely used for generating electricity, heat, and industrial steam (e.g. factories, hospitals and universities).

Compared to e.g. internal combustion engines, steam engines demonstrate the following advantages: lower maintenance requirements, lower maintenance costs, lower weight and volume. Their disadvantages are noise and greenhouse gases emissions, but still lower than in internal combustion engines.